The expectation now is that procurement will absorb every new shock: scramble for alternate suppliers, renegotiate costs on the fly, smooth over late deliveries, manage compliance risk, and still deliver savings. We’ve quietly decided this is sustainable. It’s not.

I’ve watched talented sourcing professionals — people with deep expertise and impossible workloads — burn out. Not because they weren’t good enough, but because the structure around them was built for yesterday’s business, not today’s volatility.

We can call it resilience all we want. But running constant fire drills without building fire exits is just exhaustion dressed up as strategy.

What Procurement Is Up Against

If you sit in procurement right now, you’re juggling contracts in the eye of a constant storm. The pressures hit from every direction, often all at once:

- Relentless cost pressure. Leadership sets annual savings targets as if markets are stable, while suppliers pass through inflation, raw material spikes, and labor costs. Procurement is expected to “negotiate harder” even when the math makes no sense.

- Delivery failures with cascading consequences. Late shipments are annoying and they stall multimillion-dollar programs, delay revenue recognition, and even trigger liquidated damages clauses with your own customers. Procurement is stuck in the middle, firefighting on both ends.

- Supplier instability. Key suppliers get acquired and suddenly change terms. Vendors disappear when margins shrink, leaving procurement to rebuild supply chains from scratch under impossible timelines.

- Price volatility. Steel, semiconductors, energy, freight — entire categories have been swinging wildly. Without escalation/de-escalation clauses, procurement is left to absorb the spikes or argue through change orders nobody budgeted for.

- Short-term demands vs. long-term strategy. Leadership wants immediate cost savings, while procurement knows those short-term “wins” can hollow out supplier relationships and increase long-term risk. It’s a lose-lose trap.

And through it all, there’s one constant: when the contract falls short, procurement is the one blamed.

It doesn’t matter if the warranty was written so narrowly it excluded the actual failure. Or if the termination clause was drafted in a way that trapped the business in a bad deal. Or if the renewal deadline was buried on page 17 of a PDF nobody could find.

Procurement probably didn’t write those terms, but they’re expected to enforce them, and they’re held accountable when they fail.

But vendors aren’t the problem. It’s the process. Procurement is fighting disruption with contracts and systems that weren’t designed for disruption. And that’s not a performance issue, it’s structural.

We Can’t Keep Firefighting

Let’s stop calling firefighting a strategy. It’s not. It’s proof of missing infrastructure.

Real resilience is structural. This means:

- Smarter contracting. Supplier agreements designed for disruption, not just “business as usual.” Clauses that anticipate volatility instead of pretending it doesn’t exist.

- Earlier legal involvement. Not just a signature at the end, but true alignment before the ink is dry. Legal should help shape risk allocation, not just approve it.

- Real-time insights. Contracts can’t live in shared drives or binders. If you can’t find the SLA or the pricing trigger when the supplier calls, you’ve already lost.

- Procurement in the room. Deals can’t be handed to procurement like a finished product. If they’re expected to enforce it, they need a seat at the table before the deal is signed.

The alternative is to remain in the status quo: procurement professionals running themselves into the ground, managing risk they never agreed to, with tools that don’t give them a fighting chance.

What It Looks Like When Procurement Actually Has the Tools

Resilience isn’t about working harder. It’s about working with infrastructure that’s designed for disruption. Here’s what that actually looks like in practice:

- Clause libraries that build leverage. Instead of reinventing the wheel with every supplier, procurement has a playbook: escalation clauses, backup supply triggers, enforceable warranties. When disruption hits, you’re pointing to language that’s already enforceable.

- Standard escalation frameworks. When a supplier misses a milestone, it shouldn’t trigger three weeks of internal finger-pointing. It should trigger a contractual process: notice, cure period, penalty, alternate source. Clear, predictable, enforceable.

- Contract visibility that’s real, not theoretical. Knowing there is a warranty clause isn’t enough. You need to know what it says, whether it’s enforceable, and when it expires. Imagine logging into one dashboard and seeing every upcoming renewal date, every SLA at risk, and every force majeure clause across your supplier base. That’s how we prevent “we didn’t know” disasters.

- Legal that acts like a partner, not a referee. Too often, legal gets pulled in only when something goes wrong, and procurement is already backed into a corner. True resilience means legal is involved early, helping set risk allocation and building language procurement can enforce.

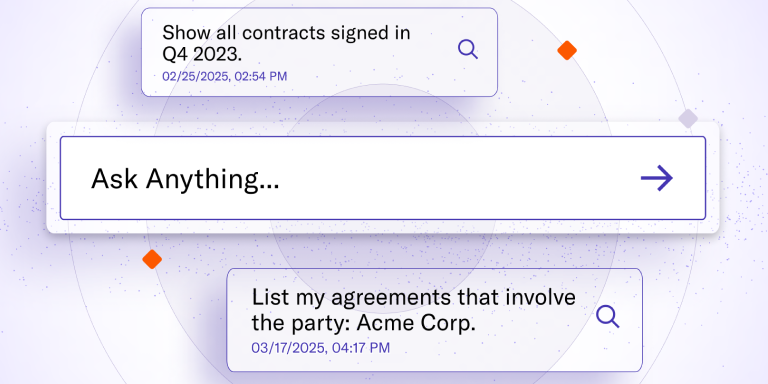

CLM platforms, like LinkSquares, are essential for syncing legal and procurement teams. They’re the connective tissue. They let Legal and Procurement work within the same source of truth. With a shared, searchable system, both sides see the same risks, the same deadlines, the same obligations. The wasted time, the second-guessing, the missed renewal windows… all disappears.

And here’s the kicker: when Procurement has these tools, the conversation changes. They stop being the department that “reacts to supplier problems” and start being the department that prevents them. That shift — from firefighter to architect — is what survival in modern supply chains actually looks like.

Procurement: smarter, not harder.

The unspoken assumption for years has been that procurement can carry infinite weight. Every crisis piles on more: negotiate faster, absorb risk, find new savings, fix the unfixable. But let’s call it what it is: unsustainable.

Procurement doesn’t need motivational speeches about grit. They need systems that keep them from being blindsided in the first place. And that means three things:

1.) Contracts built for disruption. Stop signing supplier templates that push liability uphill and assume markets never change. Build agreements that reflect reality (volatile pricing, geopolitical risk, regulatory scrutiny) and give procurement tools to enforce accountability.2.) Technology that eliminates excuses. If your contracts are scattered across inboxes and shared drives, you’re building blind. A modern CLM goes beyond “digitizing paperwork,” and creates a single system of record that turns contracts into usable, living assets.

3.) Collaboration that’s structural, not situational. Procurement and legal can’t meet only when something breaks. They need to co-own the process, from negotiation to renewal. When Legal and Procurement pull in the same direction, the business stops getting blindsided by its own contracts.

Here’s the truth: disruption isn’t slowing down. But burnout doesn’t have to be the price of survival. If we want supply chain resilience, we need to stop glorifying fire drills and start investing in fireproofing.

Procurement doesn’t need to work harder. It needs a system that lets it work smarter, so brilliant professionals can actually do the job they were hired to do, instead of burning out trying to plug holes in contracts that were never designed for this world.

Ready to Learn More About LinkSquares?

Watch our on-demand demo to learn how our CLM platform can help your team avoid unforeseen fire drills when it comes to contract management. Then schedule a custom demo here.

Subscribe to the LinkSquares Blog

Stay up to date on best practices for GCs and legal teams, current events, legal tech, and more.